-

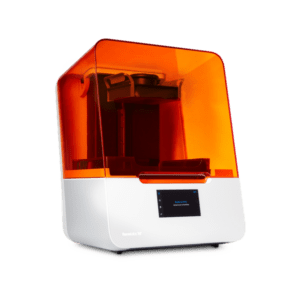

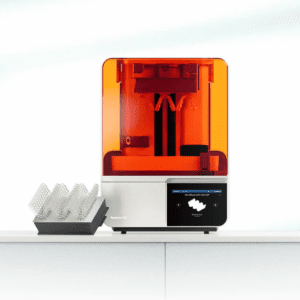

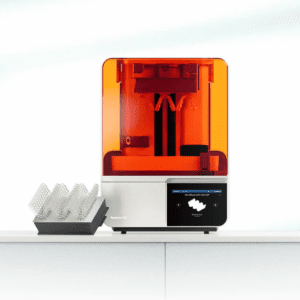

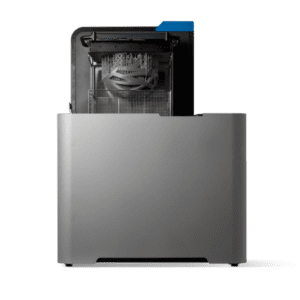

Form 3B+

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Most Trusted Dental 3D Printer

The Form 3B+ provides dental professionals with maximum performance and versatility with an easy workflow. 3D print a wide variety of dental applications in-house with minimal interaction and unrivaled print accuracy and surface finish.Fully Validated Workflows for the Practice and the Lab

The Formlabs Dental 3D printing ecosystem enables plug-and-play integration with your existing workflow for a seamless experience. The Form 3B+ is an all-encompassing digital workflow solution, including intuitive and innovative software, a resin portfolio for 10+ indications, including a wide variety of biocompatible materials, and simple, automated post-processing. No matter if you are ready to scale or engage for the first time in digital dentistry, the Form 3B+ is ready to produce high-quality parts you’ll be proud to deliver, without hassle, or prohibitive costs.Industry Leading Print Quality

The Form 3B+ is powered by our unique SLA printing process, delivering precise, unmatched surface finish and print accuracy across multiple dental applications when compared to other 3D printers. The Form 3B+ delivers: *Peace of Mind - Industry-leading print quality *Precise - Unmatched surface detail and finishing *Easy - Calibration free printingThe Easiest 3D Printer to Learn and Use

Bring dental dentistry to your practice or lab for the first time, or scale to dozens of machines, the Form 3B+ is ready to grow with your business. Your Form 3B+ comes with: One-hour personalized training call Mess-free material handling Start and track prints from anywhere with Remote Print and DashboardSimple, Low-Maintenance Resin Handling

The Form 3B+ Resin Tank lasts up to four months, reducing wasted resin and maintenance. Our cartridge system is designed to prevent spillage and keep your workspace clean, while minimizing resin waste at the same time. Spend less time cleaning your workspace and more time focusing on growing your business. After printing, use Form Wash and Form Cure streamline and automate rinsing and post-curing of prints. Clean - Spill-free resin dispense system Easy - Lightning fast and easy resin swap Efficient - Intelligent resin release systemThe Printer for Maximum Performance and Versatility

Produce a wide range of dental applications with our versatile printer and our dedicated dental resins, delivering high-performance parts with peace of mind through regulatory compliance and certified biocompatibility. https://www.youtube.com/watch?v=s94KgsbGmzc Learn more about Form 3B+ -

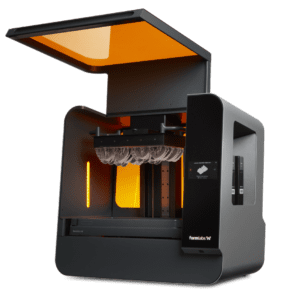

Form 3BL

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe New Standard for High Volume Dental 3D Printing

The Form 3BL is the large format dental 3D printer that raises the bar for dependable high-production dental 3D printing, designed to work day and night with minimal intervention.Maximum Productivity, Minimum Intervention

A build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) maximizes throughput for every print job. Print up to 120 models in a day, with just a few printer interactions. A Robust 3D Printing Ecosystem The Form 3BL works full time so you don’t have to. Intuitive nesting software and automated post-processing options make custom manufacturing easy. Full Arch Ort1hodontic Model Grey Resin at 100 micron layer thickness Accuracy Range: ± 100 µm Surface in Accuracy Range: 94% ± 8% *Validation parts were printed using Grey Resin on Form 3BL printers. Results may vary. Cloud monitoring Remotely monitor and inspect your fleet of printers and track resin and tank usage over time with the online Dashboard.Status alerts

Enable SMS and email notifications to receive notifications when prints are completed or your printer needs attention.Automatic resin dispensing

Our automated resin system dispenses resin as parts print. The Form 3L holds two cartridges of resin to avoid mid-print interruptions.In-house repairs

The Light Processing Units, rollers, and optics window can be replaced in-house, so you don’t have to wait for a replacement printer if something goes wrong.Designed for Nonstop Throughout

The Form 3BL is thoughtfully designed to maintain ideal print conditions with minimal operator intervention. A Team of Dental Experts Behind Formlabs Dental is a dedicated team of certified Dental Support Specialists who know exactly how to help when you need it. Our Dental Service Plan includes personalized onboarding training, proactive check-ins, and the best phone and email support in the industry. https://www.youtube.com/watch?v=rXk89kOGlmY Learn more about Form 3BL -

Form 4B Printer

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesBlazing Speed Meets Unmatched Accuracy

Unprecedented print speeds. Print a dental model every 49 seconds.Find more about Form 4B - Dental

https://www.youtube.com/watch?v=ch1T15LZeIU -

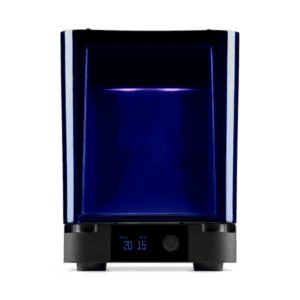

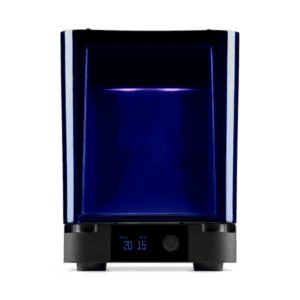

Form Cure

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Perfect Finish, Every Time

Produce parts you’ll be proud to deliver with a tried and tested, start-to-finish dental 3D printing workflow that’s certified biocompatible. All stereolithography 3D prints require rinsing and post-curing to remove uncured resin and achieve peak quality. Our automated solutions make post-processing simple. Post-Curing, Simplified Our automated post-curing solution, Form Cure, includes custom settings that maximize material performance, ensure consistent dimensional accuracy, and meet biocompatibility requirements for each Formlabs material with just the push of a button. Less Effort, Higher Throughput Form Wash and Form Cure streamline your 3D printing process so you can consistently produce high-quality parts with less time and effort. https://www.youtube.com/watch?v=JpignAVCNl8 Learn more about Form Wash + Form Cure -

Form Cure L

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesLess Effort, Higher Throughput

Streamline and automate the workflow for high-volume dental production with our large-format post-processing solutions. https://www.youtube.com/shorts/xcXqLNEHjTk -

Form Wash

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Perfect Finish, Every Time

Produce parts you’ll be proud to deliver with a tried and tested, start-to-finish dental 3D printing workflow that’s certified biocompatible. All stereolithography 3D prints require rinsing and post-curing to remove uncured resin and achieve peak quality. Our automated solutions make post-processing simple. An Automated, Thorough Rinse Form Wash agitates isopropyl alcohol (IPA) to perfectly clean your parts, then raises them to air dry once finished. Simply set the appropriate time and let Form Wash get to work. Once washing completes, parts air dry and are ready when you are. Less Effort, Higher Throughput Form Wash and Form Cure streamline your 3D printing process so you can consistently produce high-quality parts with less time and effort. https://www.youtube.com/watch?v=JpignAVCNl8 Learn more about Form Wash + Form Cure -

Form Wash (2nd Generation)

3D Scanning / Printing, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesAutomate Cleaning With Form Wash

Form Wash automatically cleans printed parts thoroughly and efficiently with IPA or alternative solvents. Keep parts directly on the Build Platform as you transition them from the printer to Form Wash, or remove parts and place them in the wash basket. Parts are precisely and thoroughly agitated in solvent with an impeller, getting every nook and cranny perfectly clean, automatically for the appropriate time. When washing completes, the Form Wash automatically raises parts out of the IPA so they can air dry. https://youtu.be/4MIWA9_TLfo -

Form Wash L

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesLess Effort, Higher Throughput

Streamline and automate the workflow for high-volume dental production with our large-format post-processing solutions. https://www.youtube.com/shorts/xcXqLNEHjTk

Printing

Home » Dental » Imaging » 3D Scanning / Printing » Printing & Consumables » Printing